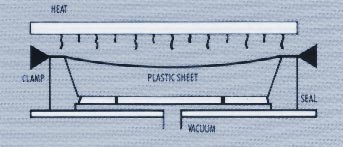

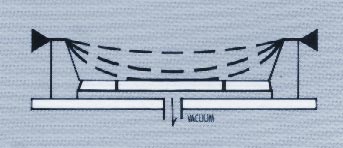

Thermoforming uses heat, vacuum and pressure to form plastic sheet material into a shape that is determined by a mould. Sheet stock is heated to a temperature at which the plastic softens but that is below its melting point. Using vacuum or pressure, the plastic is then stretched to cover and duplicate the contours of a mould. Next the plastic is cooled so it retains its shape. Finally, it is removed from the mould and trimmed as required to create a finished part.

Being a diversified custom plastics processor, we specialize in the design, fabrication and finishing of thermoformed products. Our thermoforming process includes the use of several types of plastics; high impact polystyrene, high and low density polyethylenes, ABS, co-extruded ABS and HIPS, to name a few.

Our capabilities range from prototypes and low volume runs to unlimited large volume runs, up to 32 inch x 32 inch with a 9 inch draw.

A. Heat plastic sheet is placed in the mould with vacuum applied.

B. Plastic is drawn into the mould where it is left to cool.

C. Finished mould